Company Advantages1. Production of Zhuangao helmet mould manufacturers is environmentally friendly and does not produce any water, air or noise pollution. The cleaning process ensures that it is carefully cleaned, free of dust and odor.

2. Product quality complies with current regulations and standards.

3. The product has been tested to exacting quality standards.

4. The product makes it easier to target to a more relevant audience who can be immediately impacted by the advertising of merchandise on it.

Half-face helmet plastic molded parts

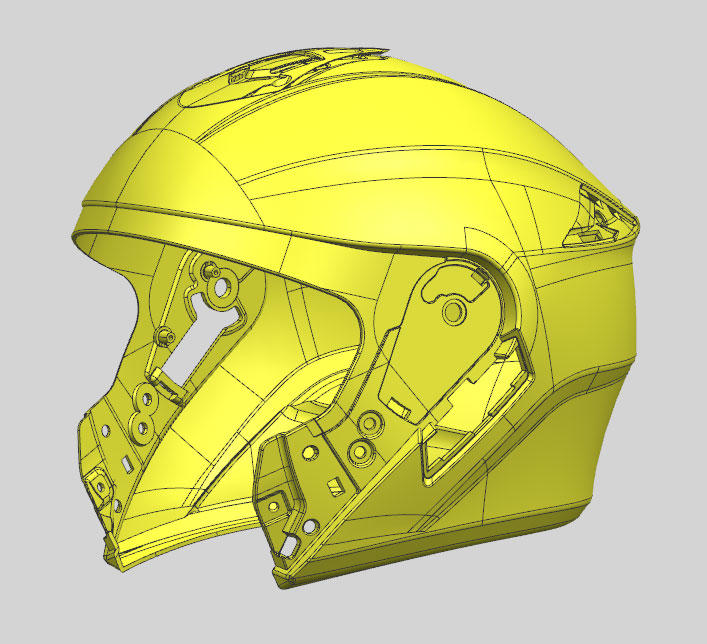

3-D product drawings of revealed helmet shell

3-D product drawings of revealed helmet shell

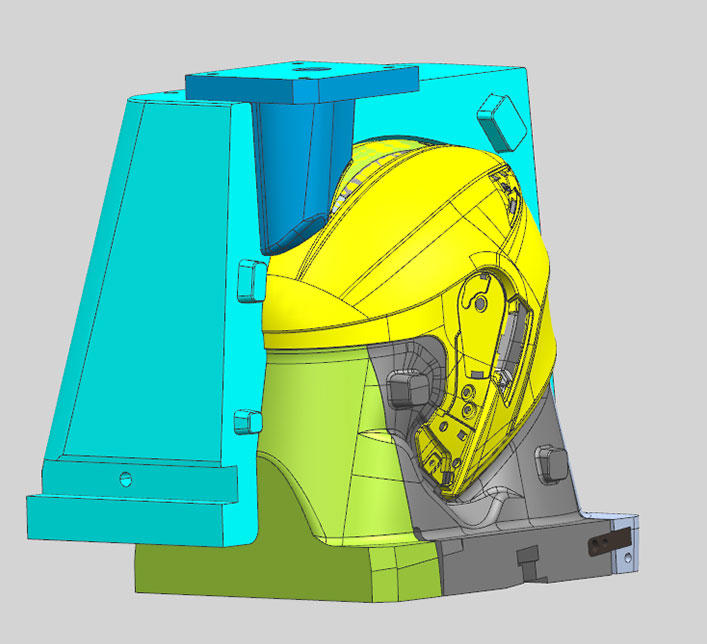

Half Helmets 3D Mould Structural Diagram, Multi-slider Mould Opening

This is the CNC machine tool processing die. CNC machine tool is the main process of die processing, so the key step of steel forming is an indispensable step in die processing. Our company has a high-precision machine tool processing, as well as three-dimensional testing, to ensure the highest processing accuracy.

Product polishing, remove the knife lines, make the surface of the die bright, while allowing products to more smoothly demould, shape bright, our company has rich experience of polishing personnel, polishing can reach the diamond level.

The company has been committed to improving the precision of machining process. Under the guidance of the strong R&D department, the company has developed strictly technical solutions and inspection standards for various processing links, and actively introduced advanced management software. At present, all the quality and progress parts of the company are under the close supervision of management software, the company can always maintain high quality molds while operating efficiently.

The company has fully implemented the modern production model and management system in management and has passed ISO9001 :2008 / ISO14001 :2004 / TS 16949 international system certification.

1

1

Precision manufacturing and processing

Company Features1. Foshan Nanhai Zhuangao Mold Co., Ltd specializes in the development, manufacture, and supply of helmet mould manufacturers and other similar products at both home and abroad.

2. There are advanced production equipment used for production of casting molds .

3. In order to better improve sustainability, we have newly introduced a green production approach. This approach has significantly promoted the reuse and recycling of raw materials and packaging materials, which reduces resource wastes. The motivation to go green has increasingly become part of our company’s social responsibility. We will use energy-efficient appliances thereby cutting energy wastage during our business practices. Our company bears social responsibilities. The physical plant of our factory presents some of the easiest, most cost-efficient ways to reduce waste. We uphold the principle of acting with integrity. We will be always honest and forthright in our dealings and build trust with clients. We pledge not to harm clients' interests.

Why choose us

1. Factory direct sales( Suzhou Factory, Xiamen 2 of factories, Hefei factory)

2. Prompt reply in 24*7 hours online.

3. Advance equipment (More than 20 sets of wire cut, Charmiles wire cutting workshop)

4. Experience engineers and workers (Almost with 15 years experience)

5. Design patents for some of small phone spare parts mold

6. Advance test machines and perfect QC system