Company Advantages1. Zhuangao making hard plastic molds is manufactured utilizing quality checked material that are obtained from the most trusted vendors of the industry.

2. Under the control of strict quality management system, the product is bound to be of a quality that conforms to the industry standard.

3. Concentrating on the quality check turns out to be effective to ensure its quality.

4. Some of our customers use it a wedding gift for the 'first home' couples without sacrificing functionality as well as style.

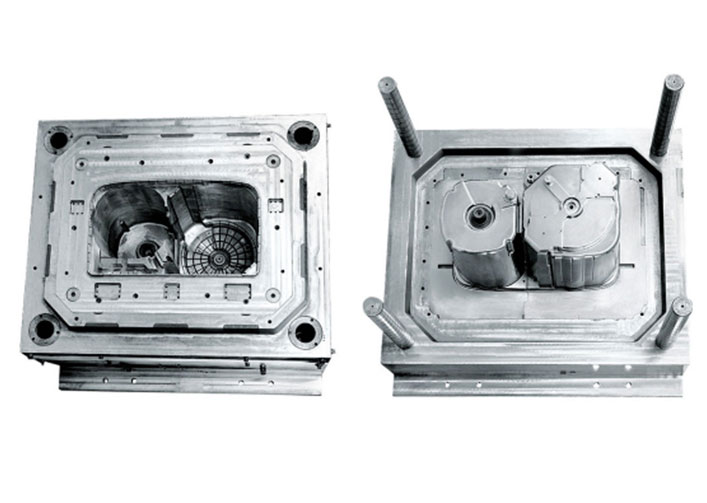

Plastic electric fan injection molding

Advantage: Our company specializes in the design and manufacture of plastic moulds. It has rich experience and technology in various types of moulds and household appliances moulds and has strong market competitiveness.

Plastic electric fan injection molding

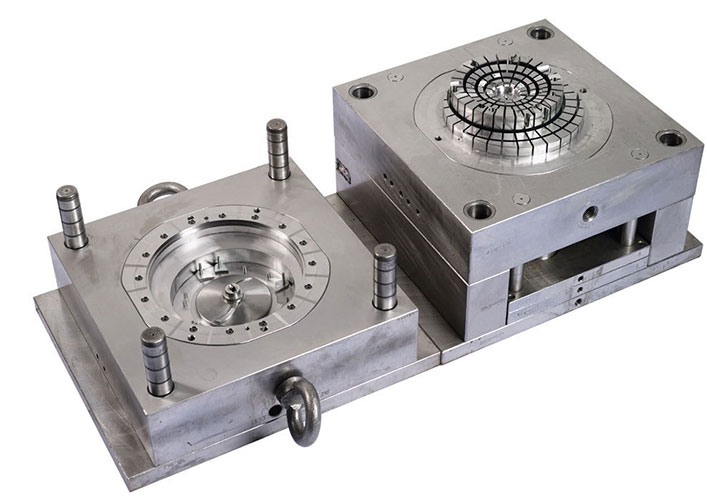

ELECTRIC FAN BLADE MOLD

SHORT PRODUCTION TIME

GOOD QUALITY GUARANTEE

CHOOSE 738H STEEL MATERIAL

COMPETITIVE PRICE

VERTICAL COOING FAN CASING MOLD

Hot runner injection process to ensure product shaping smoothly.

Adequate internal cooling design to make product shaping shorten.

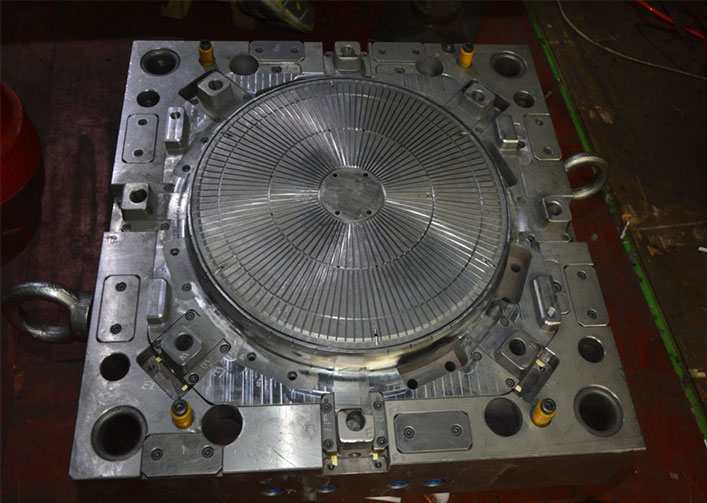

AN PLASTIC SHELL MOLDT

The whole EDM process ensures that fan plastic shell is more beautiful after molding

ELECTRIC FAN PLASTIC GRILL MOLD

FINISHED FAN PLASTIC GRILL PHOTO

The company has been committed to improving the precision of machining process. Under the guidance of the strong R&D department, the company has developed strictly technical solutions and inspection standards for various processing links, and actively introduced advanced management software. At present, all the quality and progress parts of the company are under the close supervision of management software, the company can always maintain high quality molds while operating efficiently.

The company has fully implemented the modern production model and management system in management and has passed ISO9001 :2008 / ISO14001 :2004 / TS 16949 international system certification.

1

1

Precision manufacturing and processing

Company Features1. With making hard plastic molds tailored to commercial, industrial and residential markets, Zhuangao has grown into one of the injection molded parts leaders.

2. We have an export license. This license is the foundation for us to take part in foreign trade. With this license, we are allowed to carry out overseas business on Alibaba International, Ali express, or Amazon.

3. Foshan Nanhai Zhuangao Mold Co., Ltd has after-sale service guarantee for every customer. Inquiry! The pursuing goal for Zhuangao is to make customers feel comfortable. Inquiry!