Company Advantages1. Zhuangao helmet moulding is precisely manufactured using leading-edge production techniques in line with the current market standards. It has good thermal stability and thermal fatigue resistance

2. Foshan Nanhai Zhuangao Mold Co., Ltd's technical support experts are ready to meet the various requirements of our customers. It can be processed to have better gloss for producing high-end products

3. For the future development, custom molded plastic parts is more suitable in its helmet moulding than other products. It remains good mechanical properties under high temperature

4. custom molded plastic parts has the peculiarities of helmet moulding, which is used in plastic injection molding cost . The collapsibility allows it does not cause any resistance during the contraction of the solidified casting

Precision mold for eyeglass of helmet

The product is made of ABS material, durable, strong resistance, non-toxic and harmless to human body.

(1)Our company has been engaged in the production of helmet molds for many years, and is competent in the design and manufacture of various helmet molds.

(2)We have rich experience in manufacturing helmet molds. Besides, our company understands the assembly and adjustment of various helmet structures, and can provide customers with clear suggestions and modification suggestions, which can help customers to achieve the desired product.

(3)Our company has its own research and development team, can develop a new type of helmet die structure. (4) Our company provides post-maintenance, during the maintenance period, we will help solve any problems free of charge.

Material | ABS |

Features | Durable, Strong Fighting AbilityNon-toxic, light in quality and affordable in price |

Shell dimensions | 365*260*280 |

Product Safety | It has a strong protective effect on human body in the event of accidents. |

Product characteristics | wide applicability, strong protection |

Product type | (1)The main body of the helmet--the shell

(2) all the plastic parts of the helmet

(3) the software strip in the helmet

(4)the lens of the helmet. |

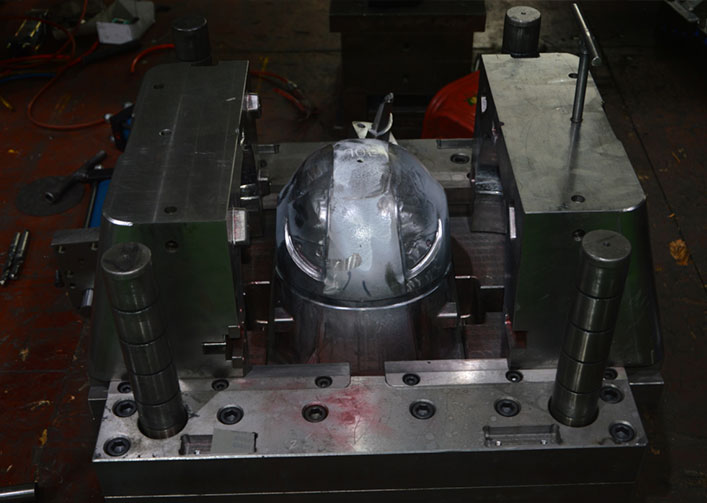

This is our design drawing of the die for the helmet. The way of pushing out the cylinder of the slider on both sides and the internal slider is adopted to make the product come out smoothly.

This is the physical drawing of the die for the helmet shell, which is the main core part.

This is the opening drawing of the helmet mould. When the slider on both sides opens the mould and the slider is ejected, the product can be taken out.

Our company make all kinds of moulds for the whole series of helmet accessories, including the main body of the helmet, as well as various accessories of the helmet.

Our company can undertake R&D-design-manufacture of helmet products, the whole manufacturing process, professional team responsibility and communication, can guarantee the quality of products, and can provide customers with the most practical and pertinent opinions, ensure the delivery and quality of moulds, adhere to the principle of customer first, including later maintenance is also omni-directional, and strive to make customers have the most satisfactory experience.

The company has been committed to improving the precision of machining process. Under the guidance of the strong R&D department, the company has developed strictly technical solutions and inspection standards for various processing links, and actively introduced advanced management software. At present, all the quality and progress parts of the company are under the close supervision of management software, the company can always maintain high quality molds while operating efficiently.

The company has fully implemented the modern production model and management system in management and has passed ISO9001 :2008 / ISO14001 :2004 / TS 16949 international system certification.

1

1

Precision manufacturing and processing

Company Features1. We have built up a clear and worthy customer base and reached a new record of numerous clients' demands, due to the expanded overseas markets. This, in turn, helps us grow stronger to win more customers.

2. We strive to find new ways of improving quality without using up more resources. We improve our products and solutions through innovations and smart thinking – to create more value at a reduced ecological footprint.