Company Advantages1. The quality control of Zhuangao injection compression molding is strictly controlled. It covers the material of aluminum, the weight of track, soundproof rate, fire safety level and so on. Its surface and edge is smooth and neat

2. From the moment I put my feet in it, I have been completely relieved of pain when walking. It gives my feet the support I need. - said one of our customers. It helps create repeatable, higher volume production parts

3. The product offers a combination of cushioning and responsiveness. The cushioning spreads the load out across the foot to reduce the impact of landing, while the responsiveness facilitates bounce back effortlessly and quickly. It has good thermal stability and thermal fatigue resistance

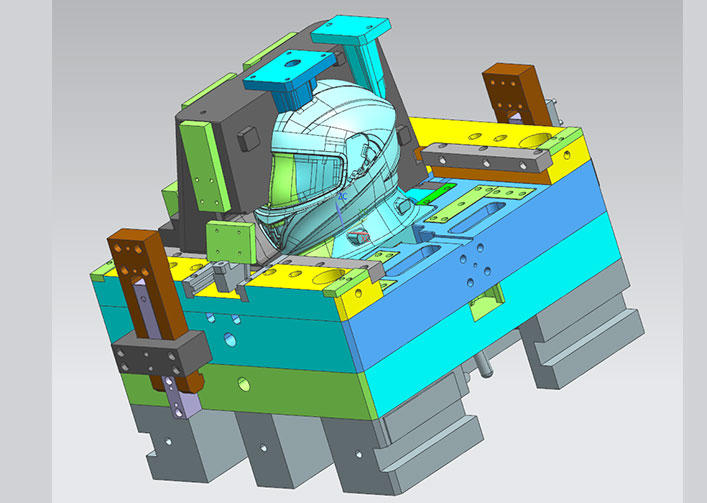

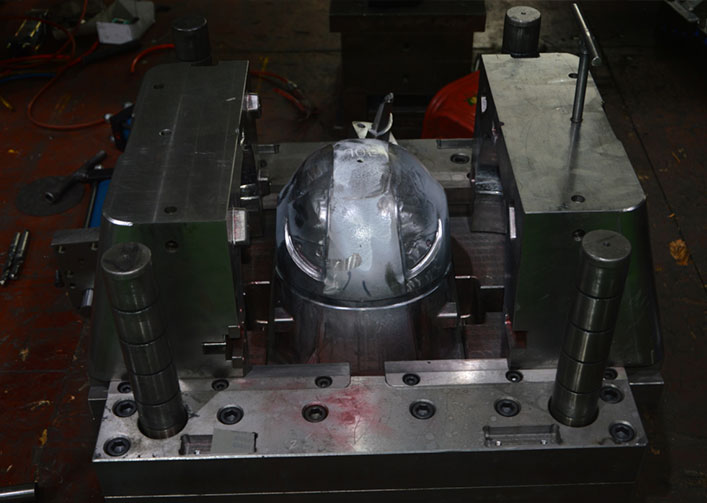

Precision mold for eyeglass of helmet

The product is made of ABS material, durable, strong resistance, non-toxic and harmless to human body.

(1)Our company has been engaged in the production of helmet molds for many years, and is competent in the design and manufacture of various helmet molds.

(2)We have rich experience in manufacturing helmet molds. Besides, our company understands the assembly and adjustment of various helmet structures, and can provide customers with clear suggestions and modification suggestions, which can help customers to achieve the desired product.

(3)Our company has its own research and development team, can develop a new type of helmet die structure. (4) Our company provides post-maintenance, during the maintenance period, we will help solve any problems free of charge.

Material | ABS |

Features | Durable, Strong Fighting AbilityNon-toxic, light in quality and affordable in price |

Shell dimensions | 365*260*280 |

Product Safety | It has a strong protective effect on human body in the event of accidents. |

Product characteristics | wide applicability, strong protection |

Product type | (1)The main body of the helmet--the shell

(2) all the plastic parts of the helmet

(3) the software strip in the helmet

(4)the lens of the helmet. |

This is our design drawing of the die for the helmet. The way of pushing out the cylinder of the slider on both sides and the internal slider is adopted to make the product come out smoothly.

This is the physical drawing of the die for the helmet shell, which is the main core part.

This is the opening drawing of the helmet mould. When the slider on both sides opens the mould and the slider is ejected, the product can be taken out.

Our company make all kinds of moulds for the whole series of helmet accessories, including the main body of the helmet, as well as various accessories of the helmet.

Our company can undertake R&D-design-manufacture of helmet products, the whole manufacturing process, professional team responsibility and communication, can guarantee the quality of products, and can provide customers with the most practical and pertinent opinions, ensure the delivery and quality of moulds, adhere to the principle of customer first, including later maintenance is also omni-directional, and strive to make customers have the most satisfactory experience.

The company has been committed to improving the precision of machining process. Under the guidance of the strong R&D department, the company has developed strictly technical solutions and inspection standards for various processing links, and actively introduced advanced management software. At present, all the quality and progress parts of the company are under the close supervision of management software, the company can always maintain high quality molds while operating efficiently.

The company has fully implemented the modern production model and management system in management and has passed ISO9001 :2008 / ISO14001 :2004 / TS 16949 international system certification.

1

1

Precision manufacturing and processing

Company Features1. Foshan Nanhai Zhuangao Mold Co., Ltd offer clients superior price performance injection compression molding . Zhuangao has its own high-tech lab to create casting molds .

2. Foshan Nanhai Zhuangao Mold Co., Ltd has a group of designers and skilled manufacturing staff.

3. The production technology of injection molding manufacturers has received extensive attention from Zhuangao. We remain faithful to improving customers satisfaction. We will devote greater effort to achieve this goal, for example, we promise to use harmless materials, ensure every piece of the product to be inspected, and offer real-time responses.