Better Touch Better Business

If you have any good suggestions, please leave a message.

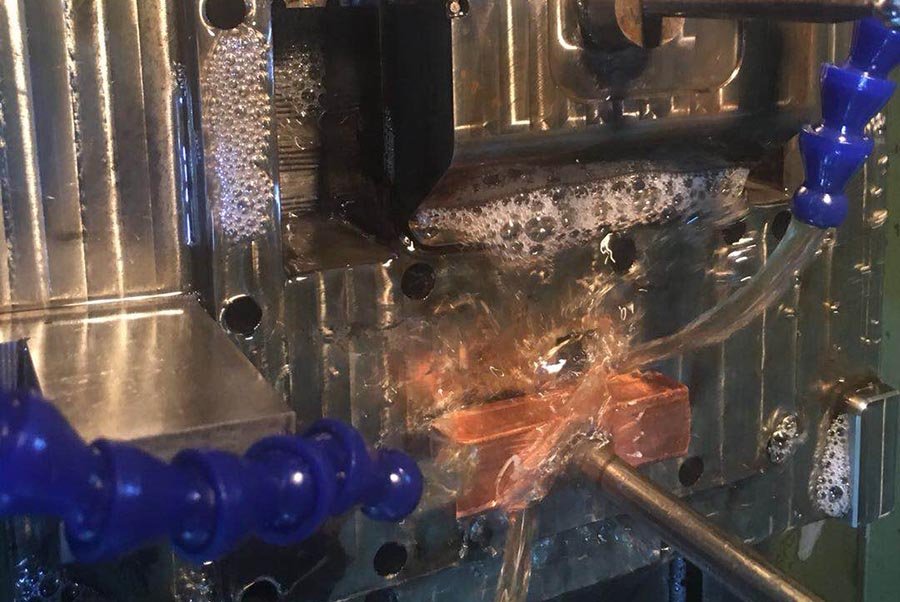

We make pipe mould for Japan has nearly 100 sets, because the mold cavity of stitching is more, high demand for product appearance, the following is the company's engineering department summary of pipe fittings mold design certificate when some of the main points, dear colleagues, please read careful study.

1. Cavity layout. According to the

geometric structure characteristics of plastic parts, size precision

requirements, batch size, mold manufacturing difficulties, mold cost and

other factors to determine the number of cavity and its arrangement.

2.

Determine the parting surface. The position of the parting surface

should be conducive to mold processing, exhaust, demoulding and molding

operations, surface quality of plastic parts, etc.

3. Determine the

casting system (shape, position and size of the main runner, runner and

gate) and the exhaust system (method of exhaust, location and size of

the vent).

4. Select the jacking method (jacking rod, jacking tube,

pushing plate and combined jacking), and determine the side concave

treatment method and core pulling method.

5. Determine the cooling

and heating modes, the shape and position of the heating and cooling

groove, and the installation position of the heating element.

6.

According to mold material, strength calculation or empirical data,

determine the thickness and dimension of mold parts, the shape and

structure, and the position of all connecting, locating and guiding

parts.

7. Determine the structural form of the main molding parts and structural parts.

8. Calculate the working dimensions of the molding parts considering the strength of each part of the mould.

Copyright © 2025 Foshan Nanhai Zhuangao Mold Co., Ltd. | All Rights Reserved