Better Touch Better Business

If you have any good suggestions, please leave a message.

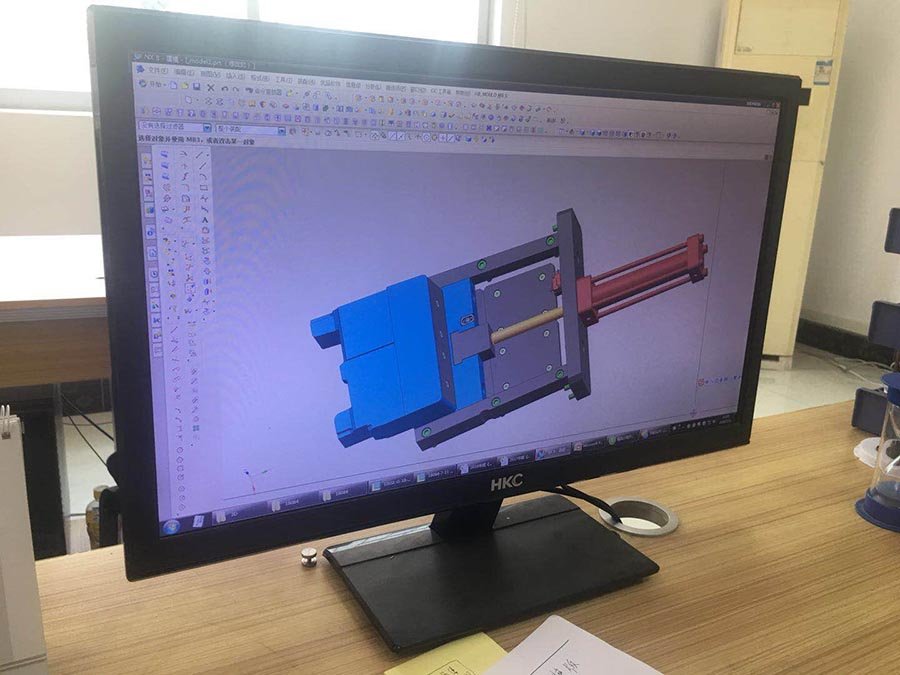

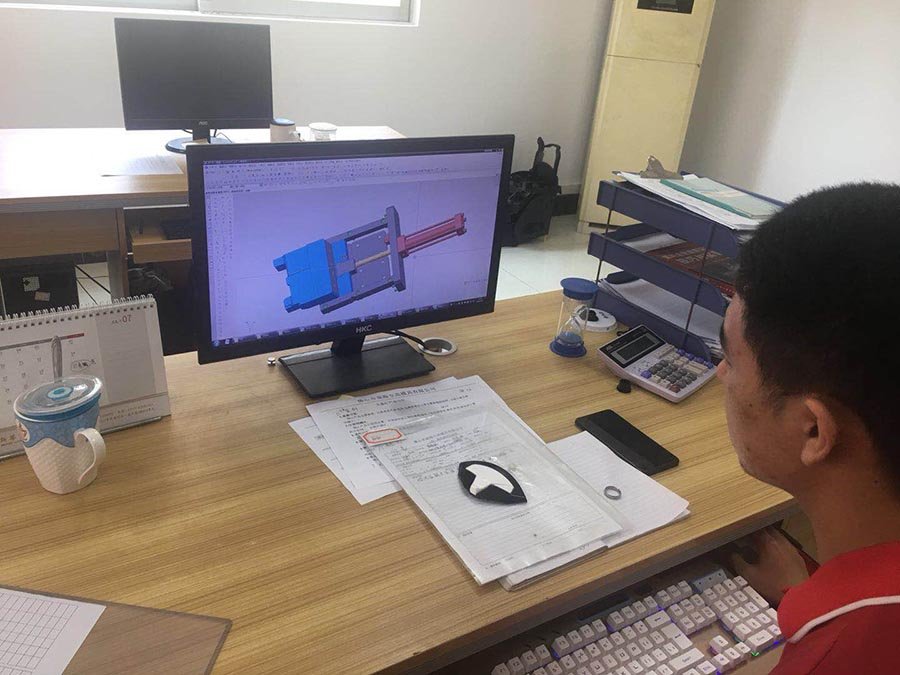

Precision injection mold with ordinary mold mold cavity dimension precision is high, is the biggest difference for mold cavity positioning and parting surface accuracy requirement is very high, therefore, the dimensional tolerance of precision injection mold needs to control the tolerance size of the products under a third.

Of precision injection molding process prone to shrinkage have thermal contraction, phase change, orientation, contraction, compression shrinkage of these four conditions, 1, thermal contraction is due to the mould temperature and the temperature is too high, lead to actual shrinkage rate increased, therefore in the process of mould processing to strictly control the mold temperature. 2. Phase change shrinkage generally occurs in the molding process of crystalline resin materials. Mold temperature affects the crystallinity, and the crystallinity increases when the temperature is too high. 3. Directional contraction can be avoided by controlling infusion speed; 4. In the case of compression shrinkage and elastic reduction, generally, the specific capacity of the molding products will be reduced by increasing the pressure, increasing the density and decreasing the expansion coefficient, so as to improve the shrinkage rate.

Copyright © 2025 Foshan Nanhai Zhuangao Mold Co., Ltd. | All Rights Reserved